The Future of Smart Fleet Maintenance Technology sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality. As technology continues to advance, the way we maintain fleets is undergoing a transformation, paving the way for increased efficiency and cost savings.

Smart fleet maintenance technology is not just a buzzword; it's a game-changer that is reshaping how companies manage their vehicle fleets. Let's delve into the key features, impact on operational efficiency, challenges, and future trends of this exciting technology.

Overview of Smart Fleet Maintenance Technology

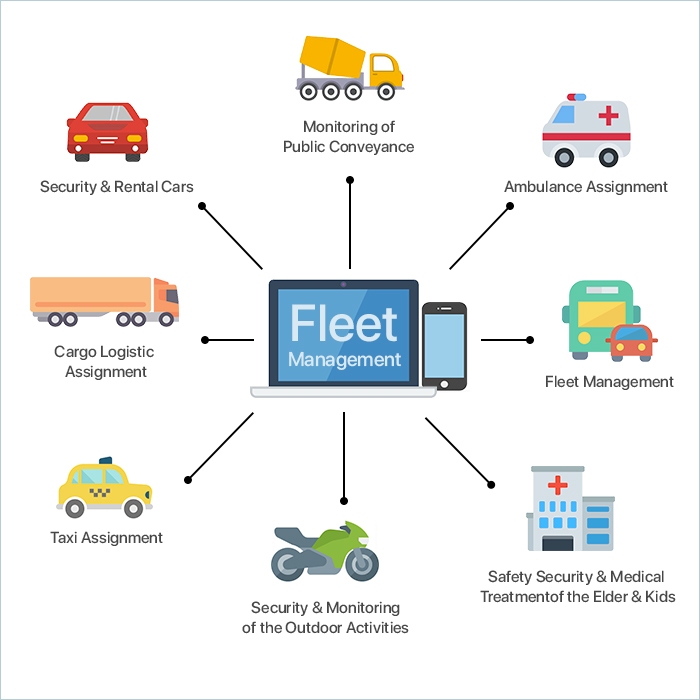

Smart fleet maintenance technology refers to the use of advanced digital tools and software to efficiently manage and maintain a fleet of vehicles. This technology leverages data analytics, sensors, and predictive maintenance algorithms to monitor the health of vehicles in real-time, identify potential issues before they occur, and optimize maintenance schedules.

Current Applications in the Industry

- Vehicle Diagnostics: Smart fleet maintenance technology allows for remote monitoring of vehicle performance metrics such as engine health, fuel efficiency, and tire pressure.

- Predictive Maintenance: By analyzing data from sensors and historical maintenance records, this technology can predict when components are likely to fail and schedule maintenance proactively.

- Optimized Routing: Fleet managers can use smart technology to optimize routes based on factors like traffic conditions, weather, and vehicle health, leading to cost savings and improved efficiency.

Benefits of Implementing Smart Fleet Maintenance Technology

- Cost Savings: Proactive maintenance and optimized routing lead to reduced downtime, lower repair costs, and improved fuel efficiency, resulting in overall cost savings for fleet operators.

- Enhanced Safety: By monitoring vehicle health in real-time and addressing issues promptly, smart fleet maintenance technology helps improve the safety of drivers and passengers on the road.

- Increased Efficiency: Automation of maintenance tasks, predictive analytics, and optimized routing contribute to increased operational efficiency and productivity within the fleet.

Key Features of Smart Fleet Maintenance Systems

Smart fleet maintenance systems incorporate several key features to ensure the efficient management and upkeep of vehicles in a fleet.

Predictive Maintenance Integration

Predictive maintenance is a crucial aspect of smart fleet maintenance systems, allowing for the proactive identification of potential issues before they escalate into costly problems. By leveraging data analytics and machine learning algorithms, these systems can predict when maintenance is needed based on factors such as vehicle usage, performance metrics, and historical data.

Role of IoT Devices

IoT devices play a significant role in smart fleet maintenance by enabling real-time monitoring and data collection from various components of the vehicles. These devices are embedded in vehicles to track metrics such as engine performance, fuel consumption, tire pressure, and more.

The data collected is then transmitted to a central system where it is analyzed to detect anomalies, schedule maintenance tasks, and optimize fleet operations.

Impact on Operational Efficiency

Smart fleet maintenance technology plays a crucial role in improving operational efficiency for companies managing fleets of vehicles. By leveraging automation and data analytics, these systems streamline maintenance processes, reduce downtime, and optimize fleet operations.

Improved Maintenance Scheduling

One key way smart fleet maintenance technology enhances operational efficiency is by enabling predictive maintenance scheduling. By analyzing data on vehicle performance and health in real-time, companies can proactively address maintenance issues before they escalate, avoiding unexpected breakdowns and costly repairs.

Enhanced Asset Utilization

Smart fleet maintenance systems help companies maximize asset utilization by providing insights into vehicle usage patterns, maintenance needs, and overall fleet performance. This data-driven approach allows companies to make informed decisions about fleet management, ensuring that vehicles are in optimal condition and available when needed.

Reduced Downtime and Costs

Automation and data analytics tools in smart fleet maintenance technology help minimize downtime by identifying maintenance needs in advance and scheduling repairs during off-peak hours. This proactive approach not only reduces operational disruptions but also lowers maintenance costs by addressing issues before they become major problems.

Real-World Examples

Companies like UPS and FedEx have successfully implemented smart fleet maintenance technology to improve operational efficiency. By utilizing predictive maintenance algorithms and real-time monitoring, these companies have reduced vehicle downtime, increased asset utilization, and optimized their overall fleet management strategies.

Optimized Routing and Fuel Efficiency

Automation features in smart fleet maintenance systems can also contribute to operational efficiency by optimizing routing and improving fuel efficiency. By analyzing data on traffic patterns, weather conditions, and vehicle performance, companies can plan more efficient routes, reduce fuel consumption, and ultimately enhance operational productivity.

Challenges and Limitations of Smart Fleet Maintenance

Implementing smart fleet maintenance technology comes with its own set of challenges. Companies often face difficulties in transitioning from traditional maintenance methods to more advanced systems. This shift requires significant investment in terms of time, resources, and training for staff members.

Moreover, integrating new technology with existing fleet management systems can be complex and may lead to operational disruptions.

Challenges Faced During Implementation

- Lack of expertise: Implementing smart fleet maintenance technology requires specialized knowledge and skills that may not be readily available within the organization.

- Data integration issues: Ensuring seamless integration of data from various sources can be a major challenge, leading to discrepancies and errors in maintenance processes.

- Resistance to change: Employees may be resistant to adopting new technologies, causing delays in implementation and affecting overall efficiency.

Limitations of Current Systems and Areas for Improvement

- Limited predictive capabilities: Current smart fleet maintenance systems may not always accurately predict maintenance needs, leading to unexpected breakdowns and downtime.

- Lack of real-time monitoring: Monitoring fleet health in real-time can be challenging with existing systems, impacting the ability to address issues promptly.

- Scalability issues: Some systems may not be easily scalable to accommodate growing fleets, causing constraints in managing maintenance activities efficiently.

Overcoming Challenges

- Invest in training: Providing adequate training to employees on how to use and leverage smart fleet maintenance technology can help overcome resistance to change and ensure successful implementation.

- Collaborate with experts: Partnering with experts in the field can help address knowledge gaps and ensure a smooth transition to advanced maintenance systems.

- Continuous improvement: Companies should continuously evaluate their systems, gather feedback from users, and make necessary enhancements to overcome limitations and improve overall efficiency.

Future Trends in Smart Fleet Maintenance Technology

The future of smart fleet maintenance technology is poised to bring about significant advancements in the industry. As technology continues to evolve at a rapid pace, we can expect to see revolutionary changes that will enhance the efficiency and effectiveness of fleet maintenance operations.

Integration of IoT and Big Data

With the increasing adoption of Internet of Things (IoT) devices and sensors in vehicles, fleet maintenance systems will have access to a wealth of real-time data. This data can be analyzed using advanced analytics tools to predict potential issues before they occur, enabling proactive maintenance strategies.

Autonomous Maintenance Systems

The development of autonomous maintenance systems powered by artificial intelligence (AI) and machine learning algorithms will revolutionize fleet maintenance. These systems will be able to detect anomalies, schedule maintenance tasks, and even perform repairs autonomously, reducing downtime and improving operational efficiency.

Predictive Maintenance with AI

AI-driven predictive maintenance algorithms will become more sophisticated, allowing fleet managers to accurately predict when maintenance is required based on the vehicle's usage patterns and performance data. This proactive approach can help prevent costly breakdowns and extend the lifespan of fleet assets.

Enhanced Remote Diagnostics

Advancements in remote diagnostic technology will enable fleet managers to monitor the health of their vehicles in real-time, regardless of their location. This capability will streamline maintenance processes, reduce manual intervention, and improve overall fleet performance.

Cloud-Based Maintenance Solutions

The shift towards cloud-based maintenance solutions will provide fleet managers with greater flexibility, scalability, and accessibility to their maintenance data. Cloud platforms will facilitate seamless collaboration between different stakeholders and enable data-driven decision-making in fleet maintenance operations.

Epilogue

In conclusion, The Future of Smart Fleet Maintenance Technology promises a future where maintenance is proactive, efficient, and cost-effective. As companies embrace this technology, they are poised to revolutionize their fleet operations and stay ahead of the competition in an ever-evolving industry landscape.

Detailed FAQs

What are the key benefits of implementing smart fleet maintenance technology?

Smart fleet maintenance technology helps companies reduce downtime, lower maintenance costs, improve vehicle safety, and optimize fleet performance through predictive maintenance and data analytics.

How can companies overcome the challenges faced when implementing smart fleet maintenance technology?

Companies can overcome challenges by investing in employee training, ensuring data accuracy, integrating systems effectively, and partnering with reliable technology providers for seamless implementation.

What emerging technologies could revolutionize the smart fleet maintenance industry in the future?

Emerging technologies such as blockchain, advanced AI algorithms, and autonomous vehicles are poised to revolutionize the smart fleet maintenance industry by enhancing data security, predictive capabilities, and overall operational efficiency.

![How to Cancel CarShield [Explained]](https://health.radartasik.id/wp-content/uploads/2025/11/Carshield-Vs-Endurance-75x75.png)

![How to Cancel CarShield [Explained]](https://health.radartasik.id/wp-content/uploads/2025/11/Carshield-Vs-Endurance-120x86.png)