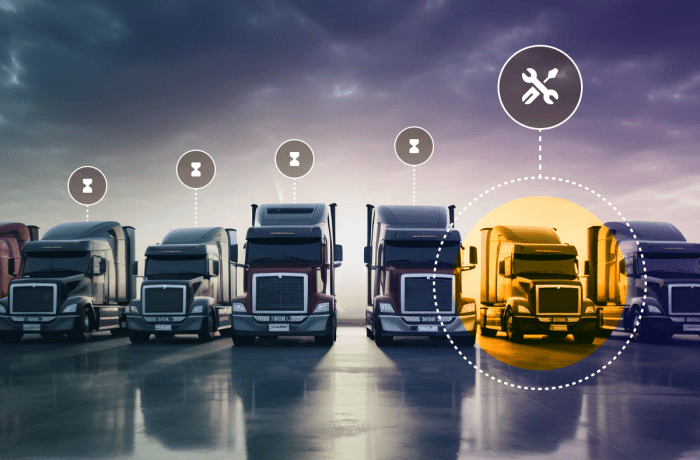

Exploring The Future of Predictive Maintenance in Fleet Operations, this introduction sets the stage for an insightful discussion on how cutting-edge technologies are reshaping maintenance practices in the transportation industry.

Detailing the pivotal role of predictive maintenance in optimizing fleet performance and ensuring seamless operations, this overview delves into the key aspects driving this transformative shift.

Importance of Predictive Maintenance in Fleet Operations

Predictive maintenance is a proactive approach to maintenance that uses data analysis, machine learning, and other technologies to predict when equipment failure might occur, allowing maintenance to be performed before the failure happens. In the context of fleet operations, predictive maintenance plays a crucial role in ensuring the vehicles are in optimal condition and minimizing unexpected breakdowns.

Benefits of Implementing Predictive Maintenance

- Cost savings: By identifying potential issues before they lead to major breakdowns, predictive maintenance helps reduce repair costs and prevent expensive downtime.

- Increased uptime: With predictive maintenance, fleet managers can schedule maintenance during off-peak hours, minimizing the impact on operations and maximizing vehicle availability.

- Extended asset life: Regular maintenance based on predictive insights can help extend the lifespan of fleet vehicles, reducing the need for premature replacements.

Optimizing Fleet Efficiency and Reducing Downtime

Predictive maintenance enables fleet managers to schedule maintenance tasks based on actual vehicle condition and usage patterns, rather than fixed time intervals. This targeted approach ensures that maintenance is performed when needed, optimizing the efficiency of the fleet and reducing downtime due to unexpected breakdowns.

Technologies Driving the Future of Predictive Maintenance

IoT (Internet of Things) has revolutionized predictive maintenance in fleet operations by enabling real-time monitoring of vehicles and equipment. Through the use of sensors and connectivity, IoT collects valuable data on the performance and condition of assets, allowing for proactive maintenance to prevent breakdowns and optimize fleet efficiency.

Role of IoT in Predictive Maintenance

IoT devices embedded in vehicles and machinery gather a wealth of information, such as engine performance, fuel consumption, and operating conditions. This data is transmitted to a centralized system where algorithms analyze patterns and trends to predict potential failures before they occur.

By leveraging IoT, fleet managers can schedule maintenance based on actual usage and condition, leading to cost savings and improved reliability.

AI and Machine Learning in Predictive Maintenance

AI and machine learning algorithms play a crucial role in predictive maintenance by processing vast amounts of data collected from IoT sensors. These technologies can identify anomalies, predict equipment failures, and recommend optimal maintenance schedules. By continuously learning from new data, AI-powered systems become more accurate over time, enhancing the effectiveness of predictive maintenance strategies.

Sensor Technologies for Predictive Maintenance

Various sensor technologies are used in fleet operations to monitor different aspects of vehicle health. For example, temperature sensors can detect overheating in engines, while vibration sensors can indicate potential mechanical issues. Additionally, GPS trackers provide location data that can be used to track vehicle usage and plan maintenance tasks accordingly.

By combining data from multiple sensors, fleet operators gain a comprehensive view of their assets and can take proactive measures to prevent downtime and reduce maintenance costs.

Challenges and Solutions in Implementing Predictive Maintenance

Implementing predictive maintenance in fleet operations comes with its own set of challenges that can hinder the effectiveness of the program. However, with the right strategies and solutions in place, these challenges can be overcome to ensure a successful predictive maintenance program that optimizes fleet performance and reduces downtime.

Common Challenges Faced:

- Lack of Data Quality: One of the major challenges in implementing predictive maintenance is the lack of high-quality data. Without accurate and reliable data, it becomes difficult to predict when maintenance is needed, leading to potential breakdowns and increased costs.

- Integration with Existing Systems: Integrating predictive maintenance technologies with existing fleet management systems can be complex and time-consuming. Ensuring seamless integration is crucial for the success of the program.

- Skill Gap: Implementing predictive maintenance requires a certain level of expertise and technical skills. A lack of skilled personnel within the organization can pose a challenge in effectively implementing and managing the program.

Solutions to Overcome Challenges:

- Invest in Data Quality: Prioritize data quality by ensuring accurate and timely data collection from IoT sensors, telematics devices, and other sources. Implement data validation processes to eliminate errors and inconsistencies.

- Collaborate with Vendors: Work closely with technology vendors to ensure smooth integration of predictive maintenance solutions with existing fleet management systems. Leverage their expertise to overcome integration challenges effectively.

- Training and Development: Invest in training programs to upskill existing workforce or hire skilled personnel with experience in predictive maintenance technologies. Building a team with the right expertise is essential for successful implementation.

The Importance of Data Quality and Analysis:

Data quality and analysis play a critical role in the success of predictive maintenance programs. High-quality data enables accurate predictions of equipment failures, allowing fleet operators to proactively schedule maintenance tasks and avoid costly downtime. Advanced analytics tools help in identifying patterns and trends in data, enabling informed decision-making and optimizing maintenance schedules for improved fleet performance.

Case Studies and Success Stories

Predictive maintenance has revolutionized fleet operations for many companies, leading to significant cost savings and operational efficiency. Let's delve into some real-world examples of how predictive maintenance has transformed maintenance strategies for fleet operators.

Example 1: Company A

- Company A, a logistics company, implemented a predictive maintenance program for their fleet of delivery vehicles. By analyzing data collected from sensors installed on each vehicle, they were able to predict maintenance needs before breakdowns occurred.

- This proactive approach led to a 20% reduction in maintenance costs and a 15% increase in fleet uptime, resulting in improved customer satisfaction and retention.

Example 2: Company B

- Company B, a transportation company, adopted predictive maintenance for their trucks and trailers. Through the use of advanced analytics and machine learning algorithms, they were able to identify patterns and trends in their fleet's performance.

- As a result, Company B saw a 25% decrease in unplanned downtime, a 30% reduction in maintenance costs, and a 10% increase in fuel efficiency, leading to substantial savings and improved operational efficiency.

Example 3: Company C

- Company C, a fleet management company, implemented predictive maintenance for their entire fleet of vehicles, including cars, vans, and buses. By leveraging predictive analytics, they were able to optimize maintenance schedules and prioritize critical repairs.

- With predictive maintenance, Company C achieved a 15% increase in asset lifespan, a 20% decrease in maintenance costs, and a 12% improvement in overall fleet performance, demonstrating the significant impact of predictive maintenance on fleet operations.

End of Discussion

Concluding our exploration of The Future of Predictive Maintenance in Fleet Operations, it's evident that embracing predictive strategies is crucial for staying ahead in the competitive landscape of fleet management.

Essential Questionnaire

How can predictive maintenance benefit fleet operations?

Predictive maintenance can enhance fleet efficiency, reduce downtime, and optimize maintenance schedules, resulting in cost savings and improved operational performance.

What are some common challenges in implementing predictive maintenance for fleets?

Common challenges include data quality issues, integration complexities, and resistance to change. Solutions involve investing in robust data analytics tools and fostering a culture of innovation within the organization.

How do IoT and AI contribute to the future of predictive maintenance in fleet operations?

IoT enables real-time monitoring of vehicle performance and health, while AI enhances predictive analytics capabilities, allowing for proactive maintenance measures based on data insights.

![How to Cancel CarShield [Explained]](https://health.radartasik.id/wp-content/uploads/2025/11/Carshield-Vs-Endurance-120x86.png)